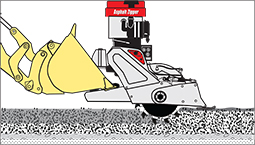

Road and highway maintenance projects requiring asphalt repair are easier and more cost-effective with Asphalt Zipper® machines. All the benefits of full-depth reclamation, stabilization, asphalt grinding and milling are in a very powerful, yet compact Asphalt Zipper grinding machine. Asphalt maintenance projects that would normally take up to one week can be done in less than one day. From small patches to up to a half a mile per day, owners report they are able to complete road repairs for less than half of what they were spending, and with better results by:

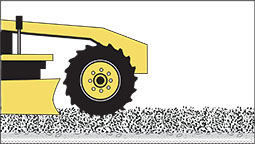

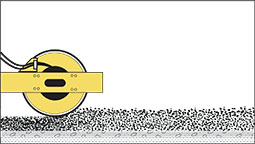

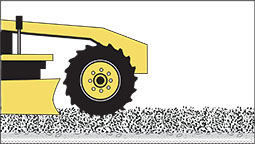

Pulverise asphalt or chip seal surface and blend with a predetermined portion of the base.* Inject water through spraybar.

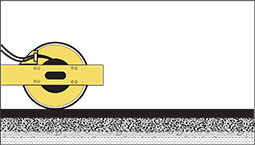

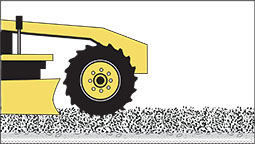

Grade and reshape. Hydrate as needed.

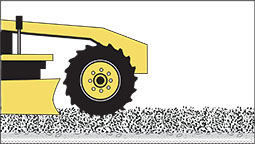

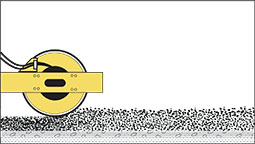

Compact with sufficient moisture.†

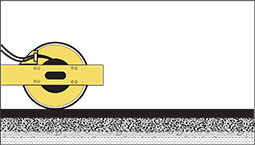

Thereafter it can be paved or sealed.

* Avoid rocks over 3 inches / 75 mm in size.

† Be sure to know the effective compaction depth of your equipment and compact in lifts if necessary. Better results are achieved using heavier vibratory compactors.

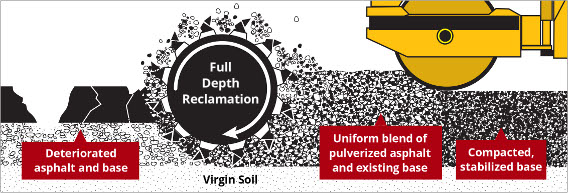

Full-Depth Reclamation (FDR) is easier and more affordable with an Asphalt Zipper® reclaimer. FDR is the process where a road reclaimer is used to reclaim or pulverize existing pavement and road materials into a reusable form, helping solve base problems, rather than just covering them up. Since the 1960’s asphalt reclamation with a large self-contained asphalt reclaimer has gained popularity but has been too expensive for many. Asphalt Zipper machines harness the benefits of road reclaimers in very powerful, yet affordable and easy to use attachments. Also see Soil Stabilization.

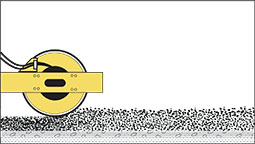

Pulverise asphalt or chip seal surface and blend with a predetermined portion of the base.* Inject water through spraybar.

Grade and reshape. Hydrate as needed.

Compact with sufficient moisture.

Thereafter it can be paved or sealed.

* Avoid rocks over 3 inches / 75 mm in size.

† Be sure to know the effective compaction depth of your equipment and compact in lifts if necessary. Better results are achieved using heavier vibratory compactors.

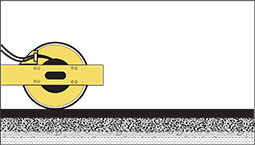

Pulverise asphalt or chip seal surface and blend with a predetermined portion of the base.* Inject water through spraybar.

Uniformly spread additional material or stabilizer (crushed rock, cement, fly ash, liquid polymer, enzyme, etc.).

Thoroughly blend material or stabilizer with a predetermined portion of the base. Hydrate as needed.

Compact with sufficient moisture.†

Thereafter it can be paved or sealed.

* Avoid rocks over 3 inches / 75 mm in size.

† Be sure to know the effective compaction depth of your equipment and compact in lifts if necessary. Better results are achieved using heavier vibratory compactors.

Pulverise asphalt or chip seal surface and blend with a predetermined portion of the base.* Inject water through spraybar.

Grade and reshape. Hydrate as needed.

Compact with sufficient moisture. †

* Avoid rocks over 3 inches / 75 mm in size.

† Be sure to know the effective compaction depth of your equipment and compact in lifts if necessary. Better results are achieved using heavier vibratory compactors.